CSW: Our Process To Ensure a Perfect Fit

We often have potential customers inquire about our process to fabricate and install countertops. With this post we provide an overview of our process, from start to finish. Read on and gain an understanding of how we utilize technology and teamwork to deliver countertops that fit and deliver on your investment.

At Canaan Stone Works, we are craftsmen. We take pride in our work and continually strive to improve upon our process, review new technology and equipment. We listen to our customers to ensure that the countertops we are fabricating and installing fit their space and their vision for that space.

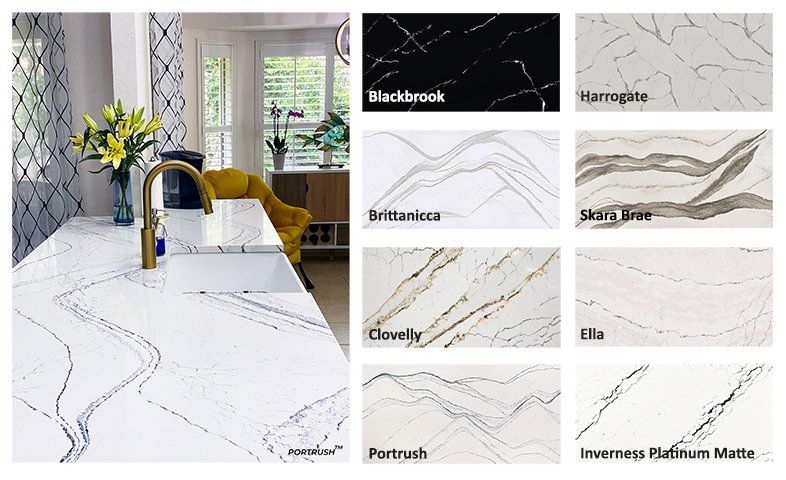

Our process for installation is built around our experience and the technology available to ensure a perfect fit. Whether the countertop is to be fabricated of granite, quartz, quartzite , or marble, we guide our customers to determine which product will be the best surface for their space.

- Begin with the end in mind. We first determine what surface material is best. This we do by showing samples at our facility or guiding our customers to one of our Selection Centers to determine material, pattern and color. We also work with custom home builders offering best product, popular color and finishes.

- Determine edge treatment. Each project and customer will want to personalize their countertop edges. We offer 7 different options – some basic and others more decorative. The tooling used to fabricate these options is unique and precise, delivering a beautifully finished edge.

- Taking measurements is key to ensuring that the custom fabricated countertops will fit into the space. Each space is measured individually to ensure the template is accurate. In order to ensure your custom countertops are fabricated to precise dimensions, we use PhotoTop® allowing us to produce fast, accurate, countertop templates with the click of a digital camera. This system allows us to do more jobs with fewer errors.

- The digital measurements for the countertop are placed on a digitizing table where exact dimensions are recorded and exported to a Computer Assisted Design (CAD) program. Here in the CAD program any modifications to the countertop are programmed as well as the specifications for the desired edge treatment and the location of holes for sinks, faucets and cook-tops.

- The digital information or Computer Numerically Controlled technology is the brains behind CNC or robotic equipment. With the introduction of CNC technology, production time has been dramatically decreased. This technology precisely controls all three types of fabrication machines, saws, polishers and routers. While the investment and equipment used to fabricate stone countertops is costly, we also choose to invest in our team of craftsmen. Without them and their knowledge to program and operate the equipment, we would not be as efficient as we are.

- Transporting finished countertops to their destination is a challenge in and of itself. Large tops with cutouts can be extremely fragile. One wrong move and the entire piece can crack or be broken. Once again, experience has taught us how to best cushion each piece and handle with “kid-gloves.” This ensures we arrive at our destination with only quality pieces to install.

- Prepping and affixing each countertop piece in its proper place is like a well choreographed dance. Tops are placed securely. Large islands or extensively long countertops are fabricated to ensure a match of pattern, color and that the seam is as invisible as possible. We pride ourselves in creating the most invisible seams in the market! Sinks are mounted and holes are drilled in the stone for the sink faucet and soap dispenser. Back-splash pieces, when ordered are fit into place. We then make any final adjustments to fit. When all of the countertop pieces come together it is a beautiful sight.

- Our install crew will clean up, take a final look around to simply enjoy the beauty of their work, then, off they go to the next location .

While no two projects are ever alike, we have invested in the technology and educated our team to be the most efficient, quality minded and customer friendly in the industry. When you choose to work with the team at CSW, you can feel confident that you have chosen one of the best, most efficient and cost effective stone fabricators & installers in the KC Metro area.

You can also see this project on our houzz projects.

Canaan Stone Works | 913.351.3500 | sales@cswkc.net

The post CSW: Our Process To Ensure a Perfect Fit appeared first on Canaan Stone Works.

All Rights Reserved | Canaan Stone Works